- Preventive Control Plans (PCP)

- Import & Export Programs

- Live Seafood Protocols

- HACCP Plans

- Food Safety Training

We Provide Food Safety Consulting & Support for Food Safety Plans for all Sizes of Companies and all Types of Industries

- HACCP Certification for Transport

- Refrigerated, Tankers, Dry Bulk

- HACCP Certification for Warehouse

- Cold/Refrigerated Storage & Dry Goods

- Managed Food Safety Programs

- Custom HACCP Plans

- Program Assessments

- Onsite Inspections

- Certification Audits

- Consulting & Support

Helping You Build the Right Plan for Your Company

Based on our experience, we understand that each company is unique and has many different types of requirements, when assessing your needs we take this into account. We will assess your industry, your company’s existing documents and procedures and then help you build the right plan that not only meets government requirements but a plan that is customized to fit your company’s unique needs.

Whether you are a food processing or packaging company, transporting or storing food, importing and exporting, we can help remove the stress and make the compliance process much easier. We do this by working with you to determine the requirements, assess what items you may already have in place through a GAP analysis, and then provide guidance in filling in any missing pieces. We also provide a digital record-keeping tool that lets you easily maintain your food safety plan for any future updates.

What are our Customers saying?

As a newcomer from visible minority and stepping up as an entrepreneur in Canada is daunting, as newcomers have less resources and networking. Thanks to google, I got connected with Ion Apple !! I had exceptionally great experience with company. Brent and Lindsay both had been very professional and have adequate knowledge to comprehend with all documents with my exporter. The strong communication, clarification of supporting documents, video call, and exchange of emails made it possible to go through the licensing process and complete it. Definitely highly recommended!Bushra T.

Kluane Canada

Brent and Lindsay worked with us to apply for the CFIA license for our exportation of marine products. Brent is responsive and friendly, and Lindsay is professional and knowledgeable. Lindsay provides valuable suggestions on our application and future follow-ups. We not only succeeded in our application but also learned how to keep our workspace well-managed following the CFIA standards. Awesome team!Jason & Xiaoguang

Wellness Trading Inc

We are a brand new company with zero experience and Lindsay at Iron Apple was extremely patient and helpful. She is also extremely knowledgeable in her field and work was completed in a very efficient and effective manner. We will continue to work with them for however long possible. Our only regret was that we did not find Iron Apple sooner.Nadia

Nadiyya The Graceful Gourmet Inc

We are really satisfied with our experience with Iron Apple and would definitely recommend your company. Our agent was helpful, and provided a lot of insight and knowledge. Always willing to go the extra mile for us and insured that the job was done in a professional and timely matter. We are so glad that we chose Iron Apple for our consulting needs.

Cristina C.

ABC Cork Co

BUILD.

MONITOR.

TRACK.

What are Preventive Controls for Food Safety?

Preventive food safety controls address hazards and risks in such areas as:

- sanitation and pest control

- treatments and processes

- equipment

- maintenance and operation of establishments

- unloading, loading and storing food

- employee competence

- employee hygiene

- employee health

- complaints and recalls

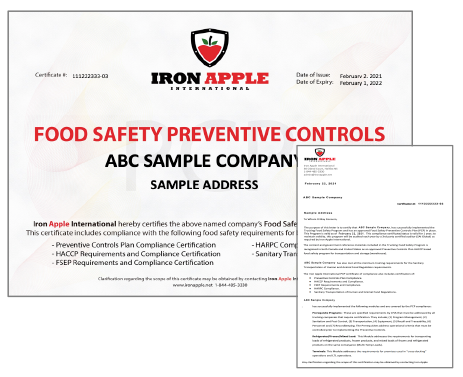

What is a Preventive Control Plan (PCP)?

For importers, a PCP describes how the importer and its foreign suppliers are meeting preventive food safety control requirements.

Industry is responsible for preparing, exporting and importing safe food. Preventive food safety controls help businesses to identify and correct issues early in the production process.

While many food businesses already have preventive controls in place, applying food safety requirements more broadly further enhances the safety of food across sectors. This better protects Canadians, helps avoid costly recalls, and ensures continued market access with countries that require similar food safety measures and mandatory control systems.

What is HACCP (Hazard Analysis Critical Control Point)?

A HACCP system is built on an establishment’s existing food safety control program. The standard operating procedures developed and written by the establishment can be Good Manufacturing Practices (GMPs) or an adopted food safety code. In many HACCP guideline documents, these GMPs are referred to as prerequisite programs that represent the foundation of the HACCP Plan.

TALK WITH OUR CONSULTANTS

To learn more about the right next step for your company, please complete the form below. We will review your request and follow up with more information.